Pursue the “essence” with tests, Haosen provides reliable Hydrogen Fuel Cell test solutions

Battery is undoubtedly the key and critical component in an electric vehicle. The battery is not only determining the characteristics of the vehicle and its performance in the driving range, but also concerns with its lifespan and safety. So, only by starting from the battery itself, digging into the battery features and acquiring actual parameters, the battery can be verified whether it meets the original design indicators, and then it is easier managed and controlled during the process of usage. Therefore, both car manufacturers and battery manufacturers need to perform overall tests for the batteries.

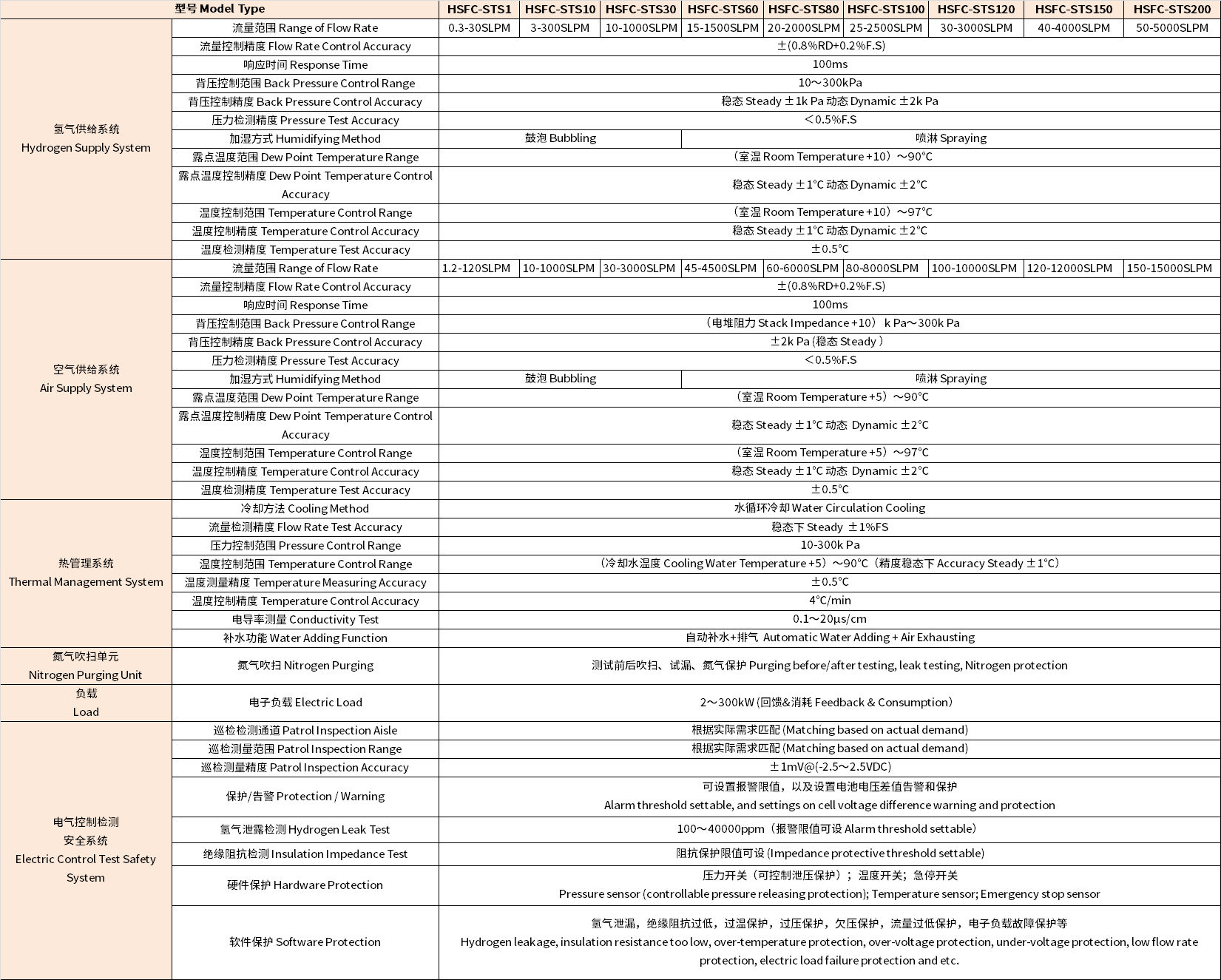

HSFC-ST Series Fuel Cell Stack Test Benches

Stack test is the core of verifying the functions of fuel cells. The stack is made of single piece of cells and the overall power is widely graded. The HSFC-ST series fuel cell stack test benches are supporting for a wide range of power and they are developed based on the researches on fuel cell testing processes and the accumulated testing experiences. The product is including anode (hydrogen) supply system, cathode (air) supply system, thermal management system, Nitrogen purging unit, electric control monitoring safety system, loads and etc. Haosen performs purposeful developing work from multiple dimensions such as developing & testing, batch delivery testing and life-testing, which are closer to various actual requirements from the stack testing process.

HSFC-ST Series Fuel Cell Stack Test Bench

Stack Test Bench Specification Parameters

Highlights:

1. The running of parameters is quick in response and is accurately controlled, humidifying dew point is controlled with an accuracy of ±1℃ (steady state) .

2. It allows manual/auto multiple running mode and allows long time unwatched running, so it is saving manpower and more efficient.

3. It is real-time collecting, saving, displaying and monitoring all running parameters and easy for data processing and equipment maintenance.

4. Integrated and iconized user interface is easy for operation and running smoothly, and the modularized structure is flexible to meet customized requirement from the customer.

5. Software and hardware are both providing safety protection and safety measures are taken according to different danger levels, giving graded alarms and providing emergency stop function to ensure the running quality.

6. Humidifying system is home-developed, it can achieve humidification highly-effectively and at the same time preventing liquid water from entering the fuel cell, the performance is reliable, easy for control and saving cost.

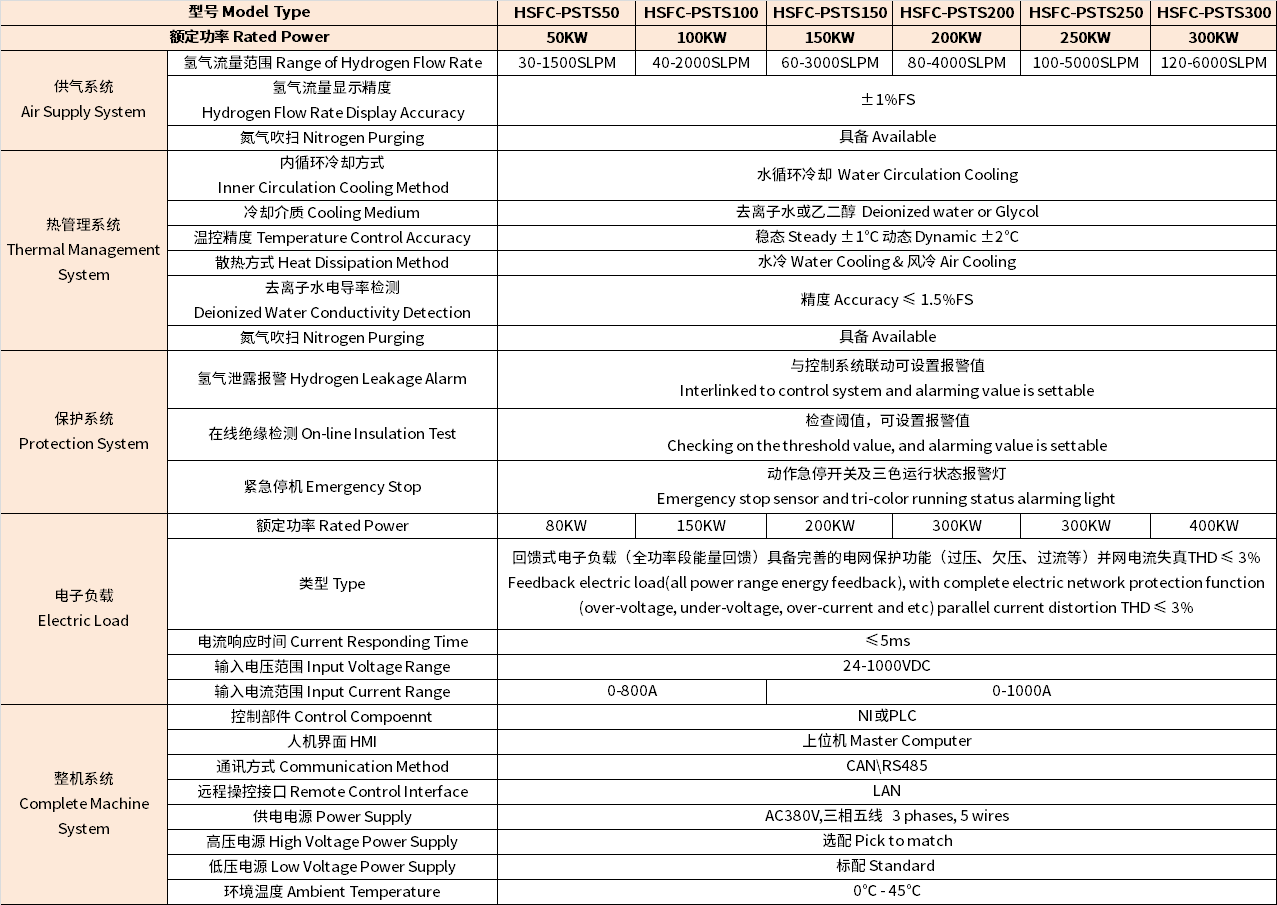

HSFC-PST Series Fuel Cell System Testing Benches

The home-developed HSFC-PST series products are platforms providing steady testing to the fuel cell system. The series are composed of air supply system, thermal management system, safeguard system, feedback electronic load and the whole machine system. This series can be used for testing on the functionality, performances, stability and safety of the fuel cell system and it is applied for the R&D of fuel cell system and offline testing.

HSFC-PST Series Fuel Cell System Test Bench

System Test Bench Specification Parameters

Highlights:

1.Home-developed thermal management system design, the temperature is safely controlled, steady control accuracy is ±1℃ and quick in response.

2.Product modularized design allows pick-to-match modules according to actual requirement and it is meeting the customized design of the customer.

3.Professional testing system software, the software development is flexible and meeting all kinds of work conditions testing requirements.

4.PC screen is clear, function is rich and operation is simple and easy so it reduces human constraints.

5.Powerful data collection and safe-guard system are easy for data processing and can perform real-time safety monitor.

6.Automatically running program editing, visualized requirement matching with the docking module of the automatic unloading and inspection.

7.It has manual/auto testing function, auto testing allows long-time unwatched running.

8.It is capable for future equipment functionality ramp-up to meet various customer demands.

Circling around the core of technology and providing solutions to the painful difficulties of the industry, and providing accurate, reliable, easy-for-operation equipment is one development directions of Haosen. From the assembly of core parts of the fuel cells, to the assembling equipment of fuel cell engine system, and to the test benches that allow tracing on parameters and quality, Haosen has been continuously enriching product series, sticking close to customer requirements and boosting for the development of the industry.