HS-Anchor Empower Digital Intelligence to Make the Future | Haosen Launches Intelligent Flexible Test Software HS-Anchor

Haosen Intelligent develops HS-Anchor (HS-安克) software based on EOL testing technology, aiming to improve the intelligence and flexibility level of domestic test software. This test software mainly serves EOL test benches for e-drives, drive motors and related products.

In the production and manufacturing process of automotive components, the EOL test bench detects quality defects in the production and manufacturing process of assembly products by running various testing processes.

The test software drives hardware devices to implement various processes, and then presents the collected data results to users. It can be said that the test software is the "cornerstone" of the entire test system-hence the name HS-Anchor. As a part of intelligent manufacturing, HS-Anchor has the future attributes of digitization, flexibility, and intelligence.

Visualization of testing process and results

Intelligence empowering data management

The digital design of the HS-Anchor main interface covers product information, test process information, operation information, key equipment status information, real-time curves, etc., making it convenient for users to master real-time data of the test process.

Today, with the development of the test software, users call for a breakthrough in the function of the product, hoping that the product can not only achieve equipment control, but also have the function of data analysis and processing. HS-Anchor can process and dynamically analyze a large amount of collected data in real time. The software algorithm supports data approaching threshold warning, accurately locating problem points, and the final results are presented in a customized chart format to assist users in judging product quality, optimizing product design and development. At the same time, AI algorithms can be used to monitor the quality of Tier-2 suppliers.

Flexible testing solutions

Flexible matching of customized requirements

The common test process for test equipment is prefabricated in PLC and test software programs, and only the basic values of the test process can be modified through the software which has low flexibility. If there is a change in the test process, requiring professionals to change both the PLC and software program which undoubtedly increases the modification time and cost of the production line.

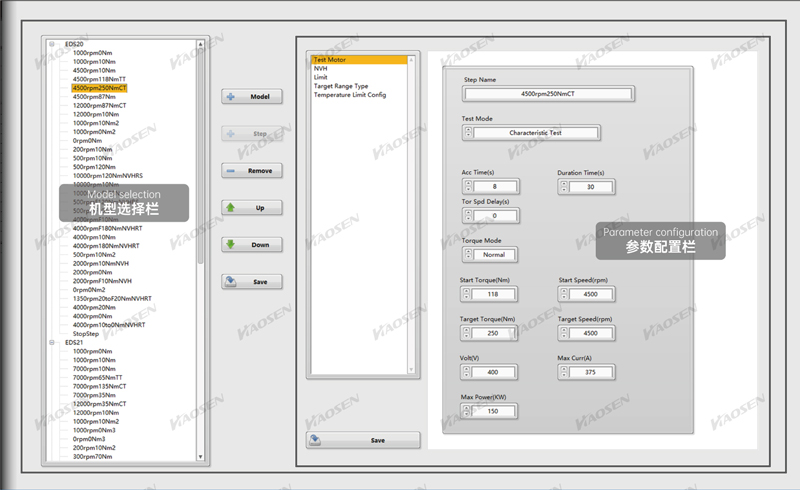

HS-Anchor is embedded with a comprehensive test process library with modular system development. New products only require users to use advanced permissions and independently configure the corresponding test process in the software configuration interface (if using a process that does not exist in the test process library, it can be customized and developed according to the user). There is no need to change the software or PLC program code, effectively saving electrical design time and shortening the modification period by 80%, and it can significantly reduce costs. In addition to functional customization, the interface display can also be customized.

HS-Anchor is developed through continuous iterative optimization and modular development of Haosen Intelligent EOL test bench software, resulting in a software system which is more systematic, functional, and responsive to the needs of future smart factories. Its wide applicability and stability have withstood multiple project tests. In the next step, Haosen Intelligent's test software technology will move towards higher intelligence and flexibility, improving the intelligence of production lines for customers and continuously matching the higher demands of global customers.